Resources

Article

Guide to Mixing FlowRPM Chemicals in a Foamer

Learn how to mix FlowRPM chemicals correctly in a foamer. Get the right dilution, avoid waste and achieve consistent ...

Learn more

Article

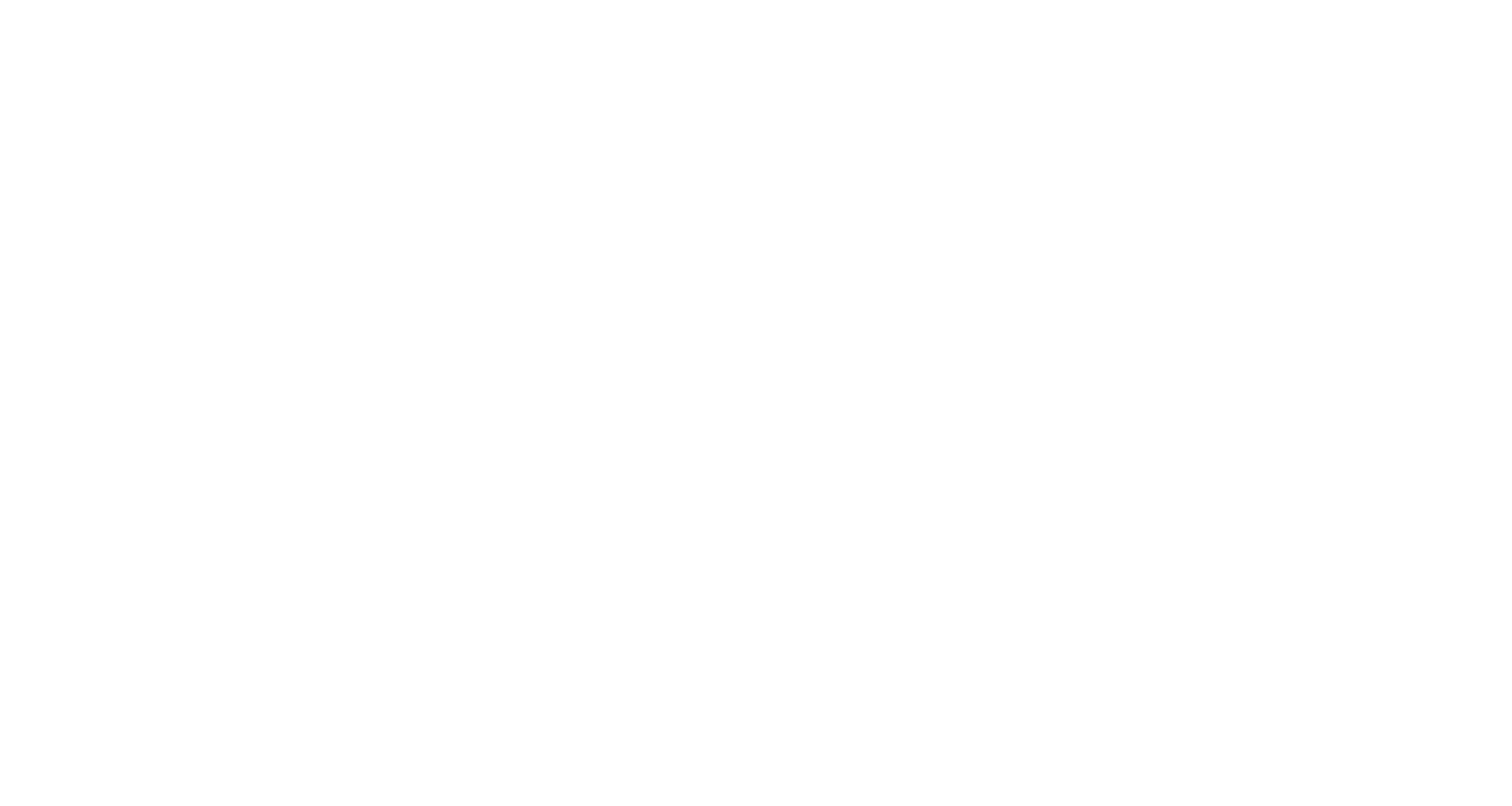

Choosing the Right Pressure Washer for Building & Property Maintenance

In this article, we take you through what to consider when choosing a SPITWATER for building and property maintenance, ...

Learn more

Article

Tough Work That Keeps Australia Safe

At Right Wash in Brisbane, Daniel Warman and his team take on the dirtiest jobs to protect Australia’s borders with ...

Learn more

Video

Product Spotlight | 10-120H

Watch how the 10-120H delivers reliable single-phase hot water pressure cleaning. This workhorse packs a powerful ...

Learn more

Article

East Coast Water Blasters Improve Heavy Fleet Cleaning with Hot Water

East Coast Water Blasters delivered a full hot water wash bay upgrade with chemical injection, safety controls and fast ...

Learn more

Article

Steven’s Bulk Services Improves Wharf Efficiency with SPITWATER SW15-200PE

Steven’s Bulk Services reduced cleaning times and sped up grain hopper turnaround with the mobile SPITWATER SW15200PE ...

Learn more

Article

Caloundra Gardens Retirement Village Keeps Roads Safe with SPITWATER

Caloundra Gardens keeps village roads safe with a SPITWATER HP2430AE system, cutting cleaning time in half and reducing ...

Learn more

Article

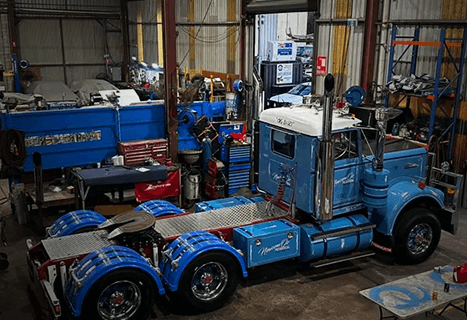

Hot Water Cleaning Transforms Workshop Efficiency at Newcomoz

Newcomoz mechanical workshop improved cleaning efficiency by 50% with the SPITWATER SW110 hot water pressure cleaner, ...

Learn more

Article

Get the Job Done Faster: Pressure Washing Solutions for Property Maintenance

Find the best SPITWATER pressure cleaner for property maintenance. Compare models for exteriors, car parks and public ...

Learn more

Find your nearest dealer.

To locate your nearest authorised SPITWATER dealer, please visit our dealer locator page. Simply enter your location to find the closest location for sales, parts, and service support.