Resources

Article

East Coast Water Blasters Improve Heavy Fleet Cleaning with Hot Water

East Coast Water Blasters delivered a full hot water wash bay upgrade with chemical injection, safety controls and fast ...

Learn more

Article

Steven’s Bulk Services Improves Wharf Efficiency with SPITWATER SW15-200PE

Steven’s Bulk Services reduced cleaning times and sped up grain hopper turnaround with the mobile SPITWATER SW15200PE ...

Learn more

Article

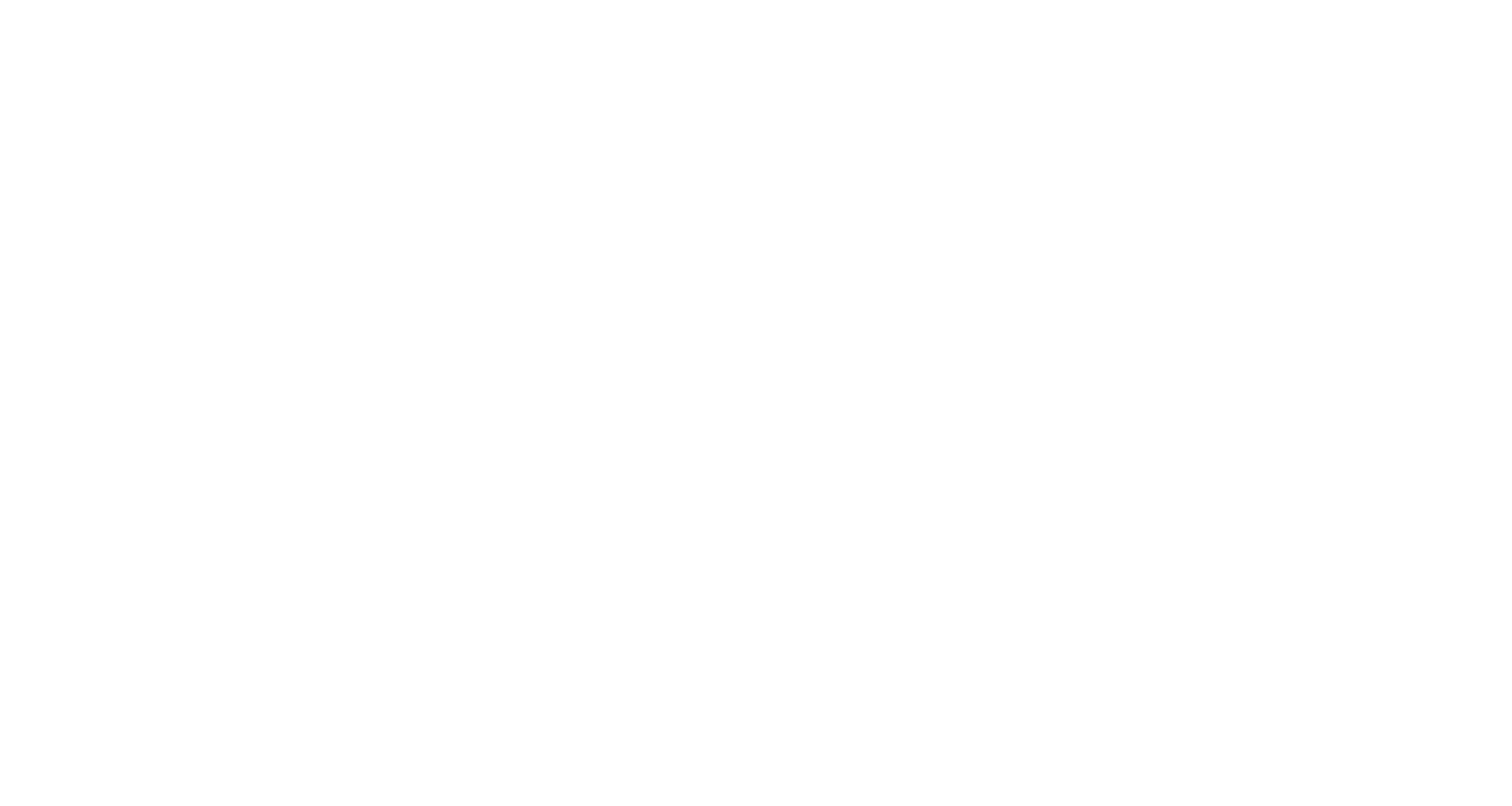

Caloundra Gardens Retirement Village Keeps Roads Safe with SPITWATER

Caloundra Gardens keeps village roads safe with a SPITWATER HP2430AE system, cutting cleaning time in half and reducing ...

Learn more

Article

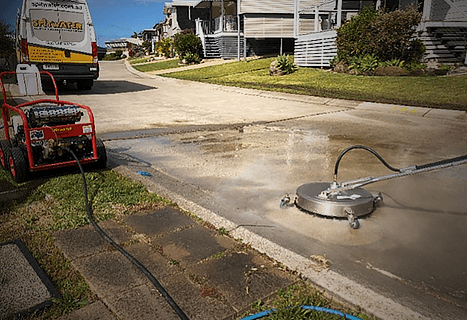

Hot Water Cleaning Transforms Workshop Efficiency at Newcomoz

Newcomoz mechanical workshop improved cleaning efficiency by 50% with the SPITWATER SW110 hot water pressure cleaner, ...

Learn more

Article

Get the Job Done Faster: Pressure Washing Solutions for Property Maintenance

Find the best SPITWATER pressure cleaner for property maintenance. Compare models for exteriors, car parks and public ...

Learn more

Article

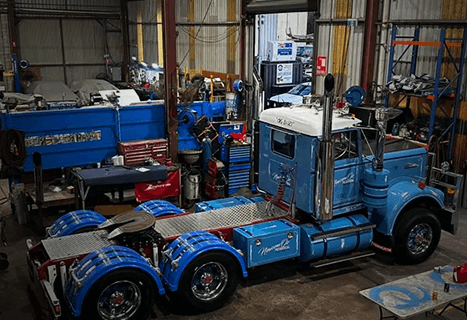

Fast-Tracked Cleaning Power: Custom Solution for Total Building Maintenance

SPITWATER built a custom ute-mounted pressure cleaning solution for TBM, delivering fast, reliable cleaning power for ...

Learn more

Article

Why Correct Flow Rate and Water Inlet Setup Matter for Pressure Washing

A pressure cleaner is only as good as its water supply. Learn why proper water inlet setup is critical for pressure ...

Learn more

Video

Tough and Ready Pressure Cleaners for Australian Agriculture

Keep your farm running with SPITWATER hot water and diesel pressure washers. Tough, reliable cleaning power for ...

Learn more

Article

Fram Cleaning Made Simple. Picking the Best Pressure Cleaner for the Job.

Learn which SPITWATER pressure washer is right for your farm jobs. From machinery wash-downs to sanitisation, find the ...

Learn more

Find your nearest dealer.

To locate your nearest authorised SPITWATER dealer, please visit our dealer locator page. Simply enter your location to find the closest location for sales, parts, and service support.